Add to Cart

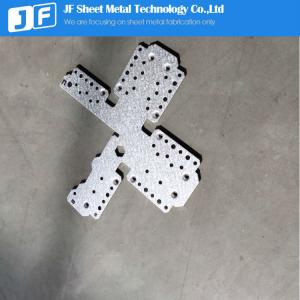

| Material | Precious Metals,Copper,Brass,Steel Alloys,Hardened Metals,Aluminum,Stainless Steel,Bronze …etc |

| Dimension | customized |

| Tolerance | +/- 0.005--0.02mm / can also be customized. |

| Prototype | accepted |

| Surface treatment | plating,mirror polishing,powder coating,anodize oxidation, e-coating,brushed,dip-coating…etc |

| Processing | laser cuting,stamping,bending,punching,CNC machining, die-casting, forming, tooling, milling, grinding,tapping,riveting,welding |

| Package | polybag/caron/wooden-case |

| Lead time | 3-15days |

| Application | car part,sever casing housing, communication equipment, intelligent terminal, airspace parts, auto sheet metal, car's navigation system, medical apparatus,drone part, LCD TV back plate, air condition, computer/advisement player, security equipment, air cleaner, water treatment equipment and electric appliance |

| Equipment | laser cutting machine, Japan Murata CNC punch, CNC Bending Machine, Large hydraulic press machine600-1200T Squeeze riveter Taiwan punch machine, CNC machining center, Precision miller, Grinder, Driller, Multi-spindle tool, argon welding/carbon dioxide welding/AC welding machine, Pipe cutting/bending machine and Polishing machine |